- Product Detail

-

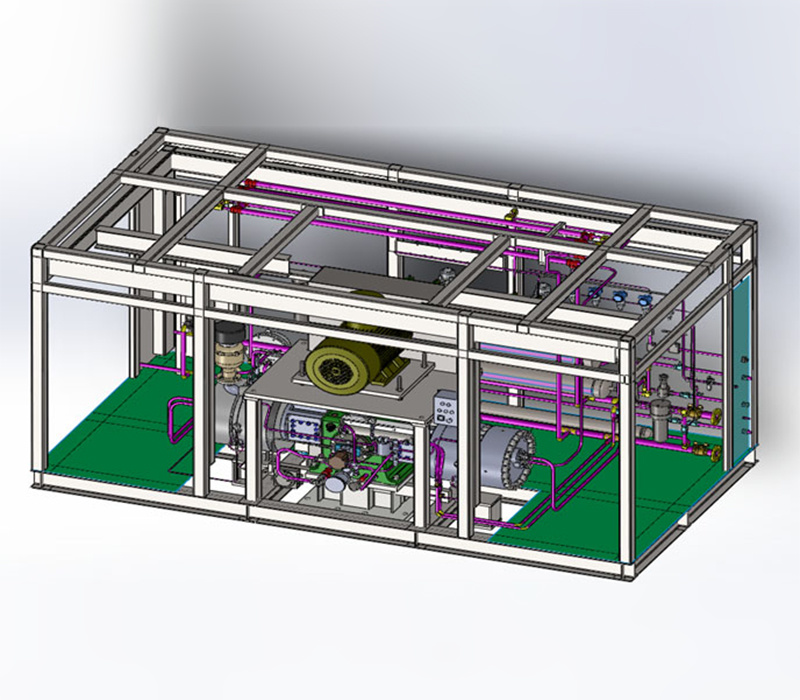

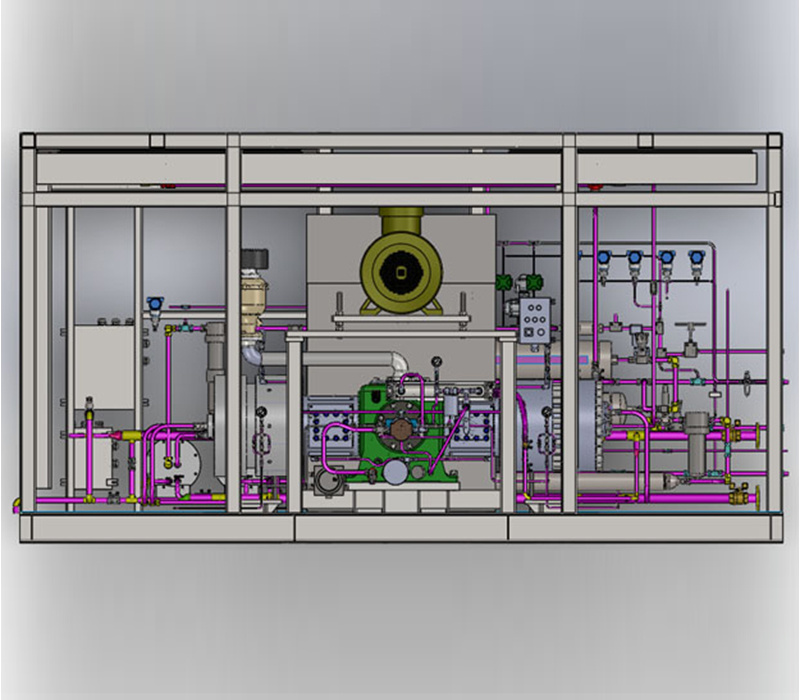

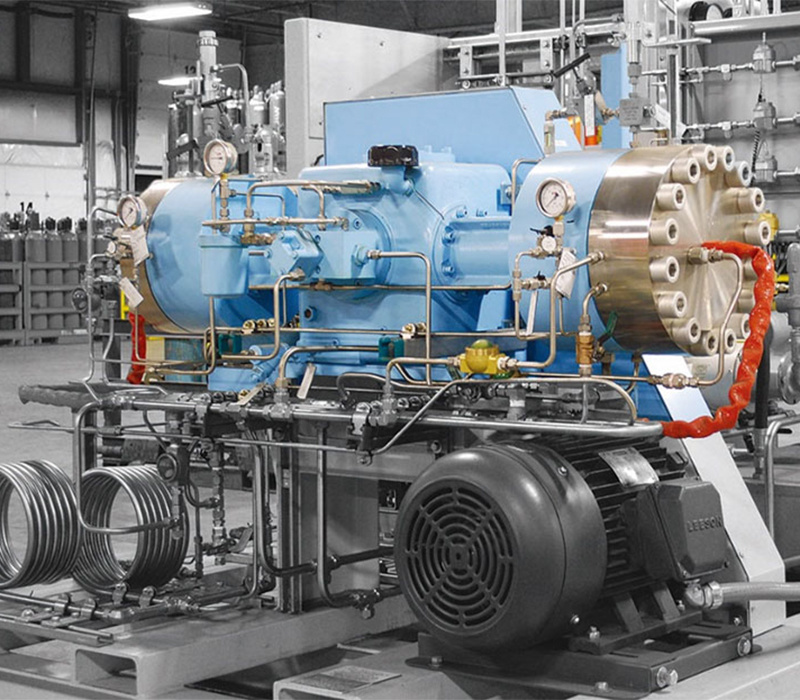

Skid-mounted Hydrogen Refueling Station - Booster Filling System Skid

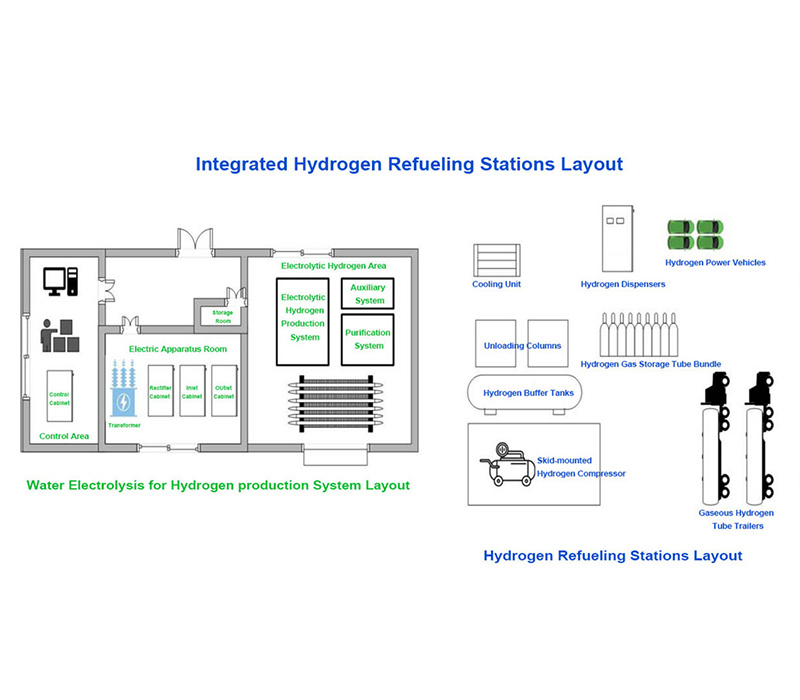

Adopting a containerized skid structure, the hydrogen dispenser is placed at the front, the compressor is located in the middle of the skid, and the sequence control cabinet is at the rear. The overall footprint is small, and it is easy to use, maintain, and highly safe. It can meet customized demands of 200-1000Kg/12h@12.5MPa hydrogen refueling at 35MPa.

Based on the core equipment of hydrogen refueling stations - hydrogen compressors (skids), discharge columns, sequence control panels, hydrogen dispensers, and station control systems, the company undertakes the customization of hydrogen refueling station equipment packages and EPC services to meet customer application needs.

Device

Configuration Details

Parameters

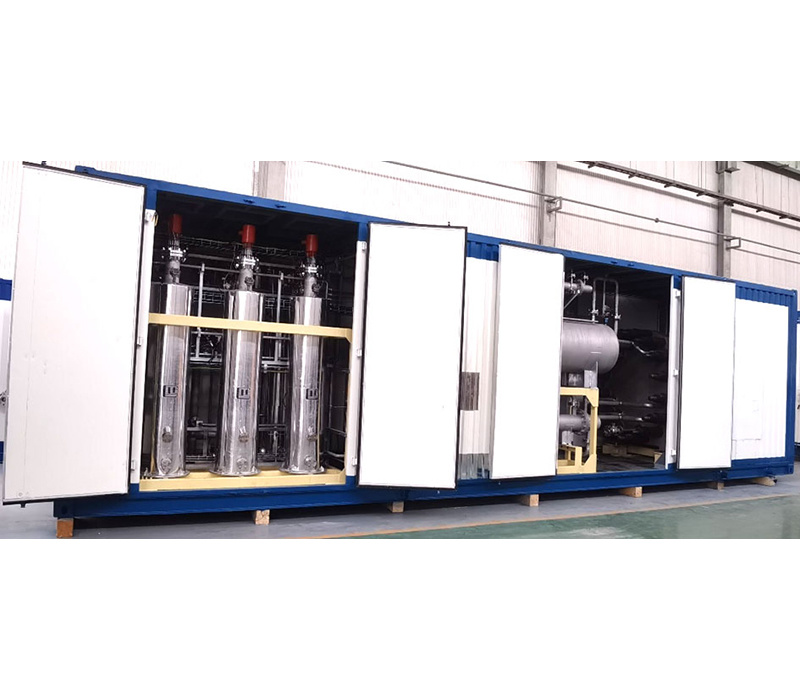

4500Nm3/h

H2 Production System

Consists of three sets of equipment, including three electrolyzers (1500 Nm³/h each), a hydrogen production framework, a purification framework, an alkaline solution tank, a water replenishment pump, a buffer tank, a rectifier transformer, a rectifier cabinet, and a low-voltage distribution cabinet

The hydrogen production capacity is 4500 Nm³/h, with a rated pressure of 1.6 MPa and a purity greater than 99.999%. The DC electricity consumption is ≤4.3 kWh/Nm³, and the system energy consumption is ≤4.8 kWh/m³, with off-peak electricity available for 7.5 hours.

Hydrogen Buffer Tanks

2 pcs

Working Pressure 1.6MPa, Water Capacity 9m³/pc

Control System for Station

The control systems for the hydrogen production and refueling devices use PLCs, implementing centralized control for the station.

The integrated station project is equipped with independent combustible gas and flame detection systems, as well as video surveillance and charging systems, to ensure the safe and stable operation of the integrated station

Cooling System

The cooling system for the supporting compressor, hydrogen dispenser, electrolyzers, and power supply utilizes a closed cooling device combined with a chiller to meet cooling requirements.

It meets the operational requirements for the safety, stability, and sustainability of the main equipment in the integrated station.

Instruments, valves, piping, and components of the control system

Selected according to the design pressure of the integrated station project

The hydrogen gas pipeline valves for the integrated station project are made of stainless steel, allowing data to be transmitted from the integrated station to external locations.

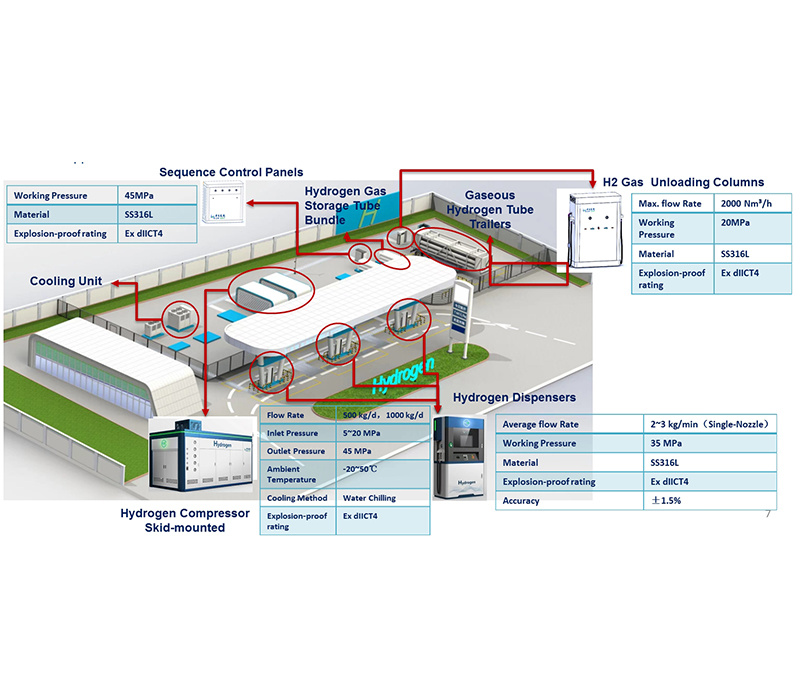

Hydrogen Compressor(22MPa)*

Adopting 22MPa reciprocating diaphragm compressor 4 sets

Inlet Pressure 1.6~5MPa,Outlet Pressure 22MPa, Flow rate 1500Nm3/h/set, 3 active 1 standby

Hydrogen Compressor(45MPa)*

Adopting 45MPa reciprocating diaphragm compressor 4 sets

Inlet Pressure 5~20MPa, Outlet Pressure45MPa, Flow rate 1500Nm3/h/set, 3 active 1 standby

Hydrogen Gas Storage Tube Bundle*

For 3000kg/day: 45MPa storage tube 80pcs, 20MPa storage tube 60pcs

45MPa Storage Tube, each tube water volume 1m3 and storage capacity of 28.877 kgs

20MPa Storage Tube, each tube water volume 2.36m3and storage capacity 35kgs

35MPa

Hydrogen Dispensers*

There are 6 hydrogen dispensers rated at 35 MPa, each equipped with a dual-meter, dual-nozzles setup. Each dispenser is configured with one TK16 and one TK25 hydrogen nozzle, allowing for simultaneous refueling. This configuration meets the hydrogen refueling needs of logistics vehicles, commuter buses, and 35 MPa heavy trucks. To ensure the safety and efficiency of rapid refueling, a pre-cooling system is included.

The average refueling speed of the 35 MPa hydrogen dispensers is ≥1.5 kg/min, in accordance with national standards, and the refueling speed is adjustable. The entire system is designed for use within an ambient temperature range of -25°C to 55°C.

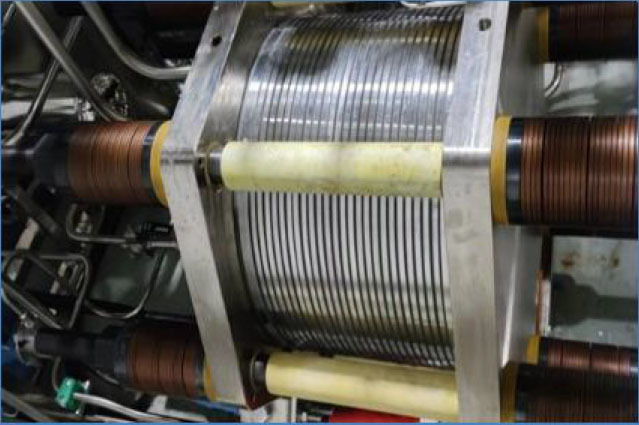

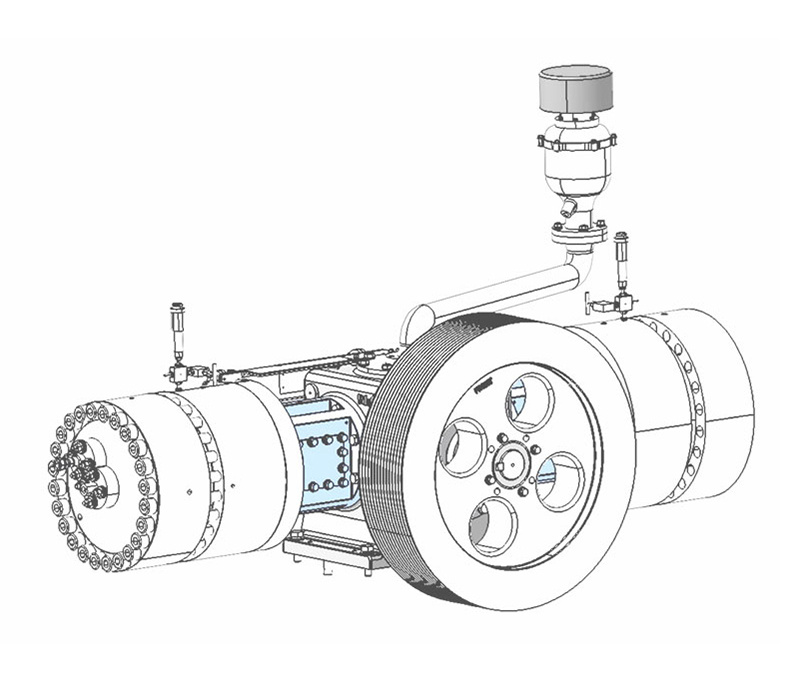

Skid-Mounted Diaphragm/ Reciprocating Compressors Compressor

Hydrogen compressors are essential components in the hydrogen economy, enabling the efficient storage, transportation, and utilization of hydrogen gas.

Types of Hydrogen Compressors

• Diaphragm Compressors: These use a flexible diaphragm to separate the compressed gas from the mechanical components, reducing the risk of contamination and improving reliability.

• Reciprocating Compressors: These use pistons to compress the gas in a series of strokes. They are suitable for high-pressure, low-volume applications.

• Screw Compressors: These use intermeshing screws to compress the gas. They are known for their high efficiency and low maintenance requirements.

• Centrifugal Compressors: These use centrifugal force to compress the gas. They are suitable for high-volume, low-pressure applications.

In hydrogen stations, diaphragm compressors and Reciprocating (Hydraulic-driven ) Compressors are two commonly used types of hydrogen compressors.

The choice of which compressor depends on the following factors:

• Hydrogen purity requirements

• Compression ratio and discharge pressure

• Operating conditions

• Budget

Comparison of Diaphragm Compressors and Liquid-Ring Compressors in Hydrogen Stations

Feature

Diaphragm Compressor

Reciprocating Compressors

Advantages

Excellent sealing, no leakage; High compression ratio and discharge pressure; Easy maintenance; Versatility

Simple structure, low maintenance cost; Frequent start-stop; High efficiency; Small size, light weight

Disadvantages

Higher cost; Limited lifespan; Higher noise level; Limited number of start-stop cycles

High sealing requirements; High requirements for hydraulic oil; Higher noise level

Suitable Scenarios

High-purity hydrogen compression, applications with high compression ratio and discharge pressure requirements

Frequent start-stop, cost-sensitive applications, space-constrained environments

Skid-mounted Diaphragm Hydrogen Compressor

Parameters

Flow Rate

500 kg/d

1000 kg/d

Inlet Pressure

5~20 MPa

5~20 MPa

Inlet Temperature

≤ 30 °C

≤ 30°C

Outlet Pressure

45 MPa(MAX)

45 MPa(MAX)

Outlet Temperature

~55 °C

~55°C

Explosion-proof rating

Ex dIICT4

Ex dIICT4

Skid-Mounted Hydraulic-driven Compressor

Parameters

Flow Rate

500 kg/d

1000 kg/d

Inlet Pressure

5~20 MPa

5~20 MPa

Inlet Temperature

<45 °C

<45°C

Outlet Pressure

20 MPa

45 MPa

Outlet Temperature

≈45°C

≈45 °C

Explosion-proof rating

Ex dIICT4

Ex dIICT4

Hydrogen Dispenser

A hydrogen dispenser includes high-pressure pipelines, valves, filling nozzles, metering, and pricing display components and functions. It is used to safely fill hydrogen into the on-board hydrogen storage tanks of fuel cell vehicles.

The hydrogen supply pipeline is a single-line, dual-nozzle system, equipped with one TK25 and one TK16 filling nozzle.

Key Specifications and Features of Hydrogen Dispenser

Serial No.

Item

Parameters

1

Medium

Compressed hydrogen

2

Peak flow rate

0~3.6Kg/m

3

Maximum pressure

35MPa

4

Design pressure

49.5MPa

5

Ambient temperature

-25°C ~55°C

6

Metering accuracy

±2.5%

7

Metering repeatability

±1%

8

Protection level

IP55

9

Explosion-proof level

Ex DIICT4

10

Hydrogen-containing materials

SS316L

11

Filling mode

dual-nozzle system

12

Filling nozzle model

TK16、TK25

Skid-mounted Hydrogen Refueling Station

Adopting a containerized skid structure, the hydrogen dispenser is placed at the front, the compressor is located in the middle of the skid, and the sequence control cabinet is at the rear. The overall footprint is small, and it is easy to use, maintain, and highly safe. It can meet customized demands of 200-1000Kg/12h@12.5MPa hydrogen refueling at 35MPa.

Categories:

keyword:

Skid-mounted Hydrogen Refueling Station

Factory

FAQ

Related Projects

Related Product