Indonesia Project

Date: 2024-12-31

Air Separation Unit (ASU): A Brief Introduction

Air Separation Unit (ASU) is an industrial facility that separates atmospheric air into its primary components: nitrogen, oxygen, and sometimes argon. This process is achieved through a series of complex steps that involve cooling the air to extremely low temperatures (cryogenic temperatures).

• Air Intake and Filtration: Atmospheric air is drawn into the ASU and filtered to remove impurities like dust and moisture.

• Compression: The filtered air is compressed to increase its pressure.

• Cooling and Purification: The compressed air is cooled and further purified to remove any remaining contaminants.

• Cryogenic Separation: The cooled, purified air is then cooled to extremely low temperatures, causing it to liquefy.

The liquefied air is separated into its components through a process called fractional distillation, where different gases are separated based on their boiling points.

• Product Gas: The separated gases, nitrogen, oxygen, and argon, are then warmed and compressed to their final state, ready for storage or distribution.

The gases produced by ASU have a wide range of applications across various industries:

• Oxygen:

♦ Steelmaking

♦ Medical applications

♦ Chemical production

• Nitrogen:

♦ Food preservation

♦ Electronics manufacturing

♦ Chemical production

• Argon:

♦ Welding

♦ Metal fabrication

♦ Lighting

By efficiently separating the components of air, ASU play a crucial role in modern industries, contributing to technological advancements and supporting various essential processes.

Comparison of Air Separation Units (ASUs): External Compression, Internal Compression, High-Purity Nitrogen, and Argon Recovery Units

1. External Compression Air Separation Unit

• Working Principle: The low-pressure gas from the cold box is compressed to the desired pressure by external compressors.

• Process Characteristics: Expanded air enters the upper column, with a smaller liquid volume and lower product pressure (generally less than 3.0MPa).

• Advantages: Relatively simple structure and easy maintenance.

• Applications: Suitable for applications with low product pressure requirements and less demanding system complexity.

2. Internal Compression Air Separation Unit

• Working Principle: The liquid oxygen/nitrogen is pressurized by low-temperature liquid pumps and then reheated before entering the user's pipeline.

• Process Characteristics:Expanded air enters the lower column, with a larger liquid volume and higher product pressure (generally less than 10.0MPa).

• Advantages: High product pressure to meet high-pressure gas demands.

• Applications: Suitable for applications with high product pressure requirements and can tolerate higher system complexity.

3. High-Purity Nitrogen Unit

• Working Principle: Produces high-purity nitrogen and liquid nitrogen through the air separation process.

• Process Characteristics: Various process types can be selected based on requirements.

• Advantages: High product purity to meet various application requirements.

• Applications: Widely used in electronics, chemical, metallurgical, and other industries where high-purity nitrogen is required.

4. Argon Recovery Unit

• Working Principle: Separates argon from mixed gases to recover argon.

• Advantages: Reduces production costs, saves energy, and improves economic benefits.

• Applications: Suitable for applications with large argon demand and argon-containing waste gas.

Summary of Comparison

|

Unit |

Working Principle |

Process Characteristics |

Advantages |

Applications |

|

External Compression ASU |

External compressor pressurization |

Expanded air enters upper column, small liquid volume, low pressure |

Simple structure, easy maintenance |

Low pressure requirement, low system complexity |

|

Internal Compression ASU |

Low-temperature liquid pump pressurization |

Expanded air enters lower column, large liquid volume, high pressure |

High pressure |

High pressure requirement, can tolerate higher system complexity |

|

High-Purity Nitrogen Unit |

Air separation process |

Various process types |

High product purity |

Electronics, chemical, metallurgical industries |

|

Argon Recovery Unit |

Mixed gas separation |

- |

Reduces costs, saves energy |

Large argon demand, argon-containing waste gas |

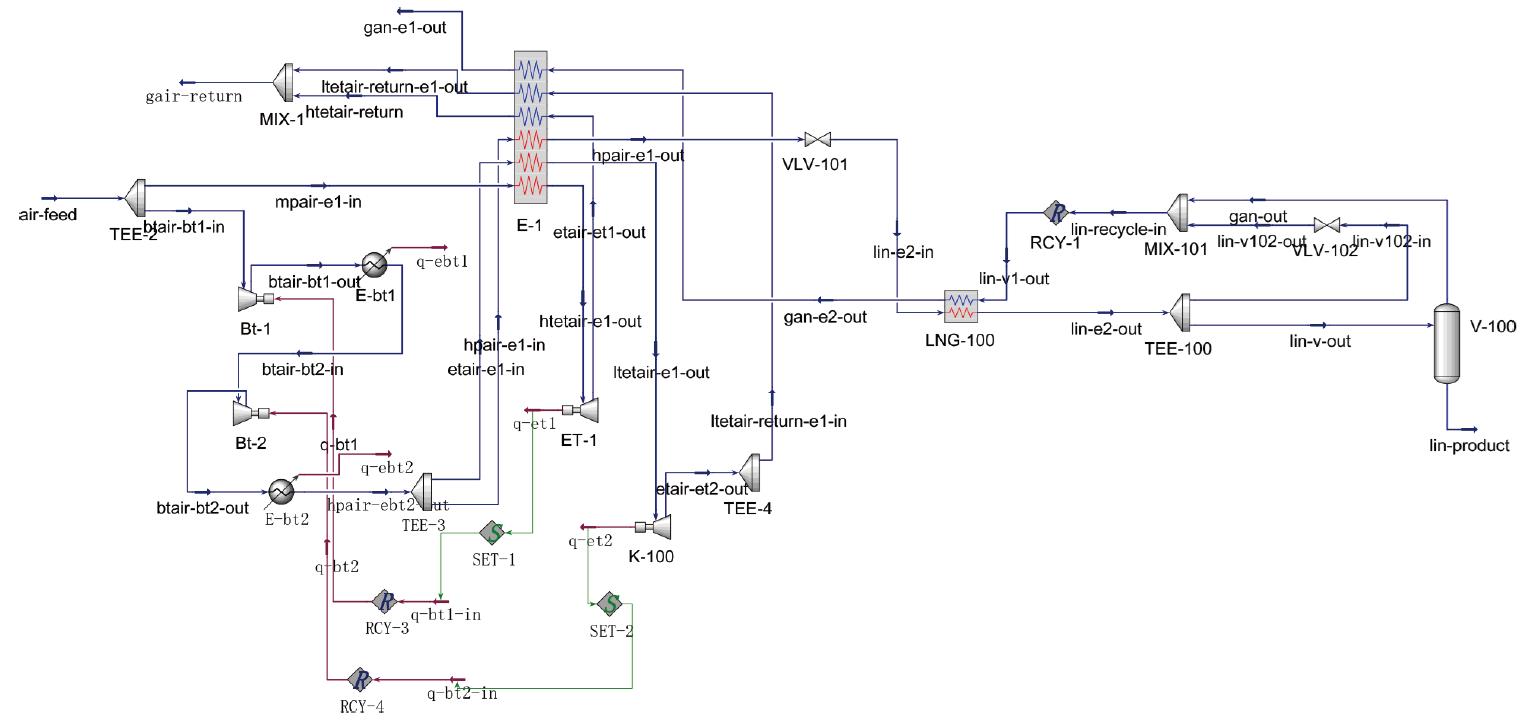

5. Liquid Air Separation Plant

A liquid air separation plant can be considered a combination of an air separation plant and a liquefaction plant. Its refrigeration and heat exchange systems are similar to those found in liquefaction plants of comparable capacity. The appropriate refrigeration cycle should be selected based on the required capacity. Four typical processes are as follows:Low pressure cycle

• Low pressure cycle with cryogenic freezer

• Medium pressure cycle

• Medium pressure double expansion process

The product is generally a fully liquid product, and some gaseous byproducts can be produced as required.

6. Liquefaction Plant

Oxygen, nitrogen, LNG, CNG, and special gases are liquefied using the sufficient cold generated by a cyclic boosting expansion process, employing recycle compressors and expanders.

Process Features

• Low pressure cycle

• Low pressure cycle with cryogenic freezer

• Medium pressure cycle with warm and cold expansion turbines

Liquid oxygen and liquid nitrogen can be produced separately or simultaneously.

The choice of unit depends on the following factors:

• Product Pressure Requirements: For high product pressure requirements, choose an internal compression ASU.

• Product Purity Requirements: For high product purity requirements, choose a high-purity nitrogen unit.

• Economy: For large argon demand and argon-containing waste gas, choose an argon recovery unit.

• System Complexity: For low system complexity requirements, choose an external compression ASU

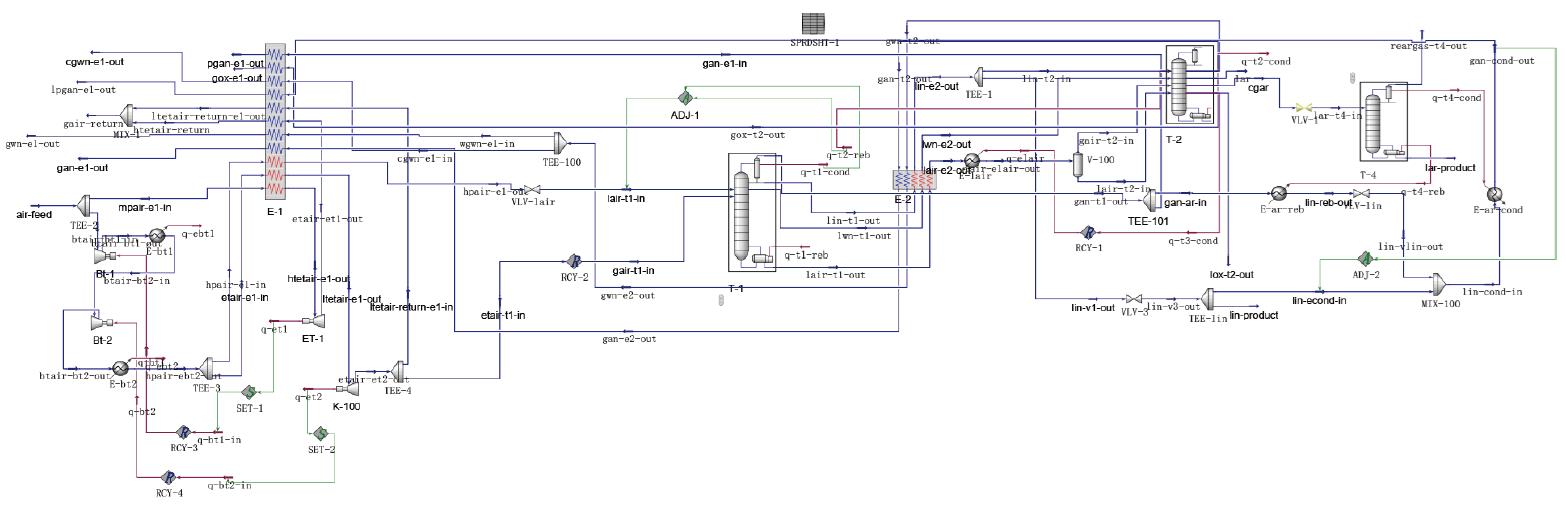

Workflows

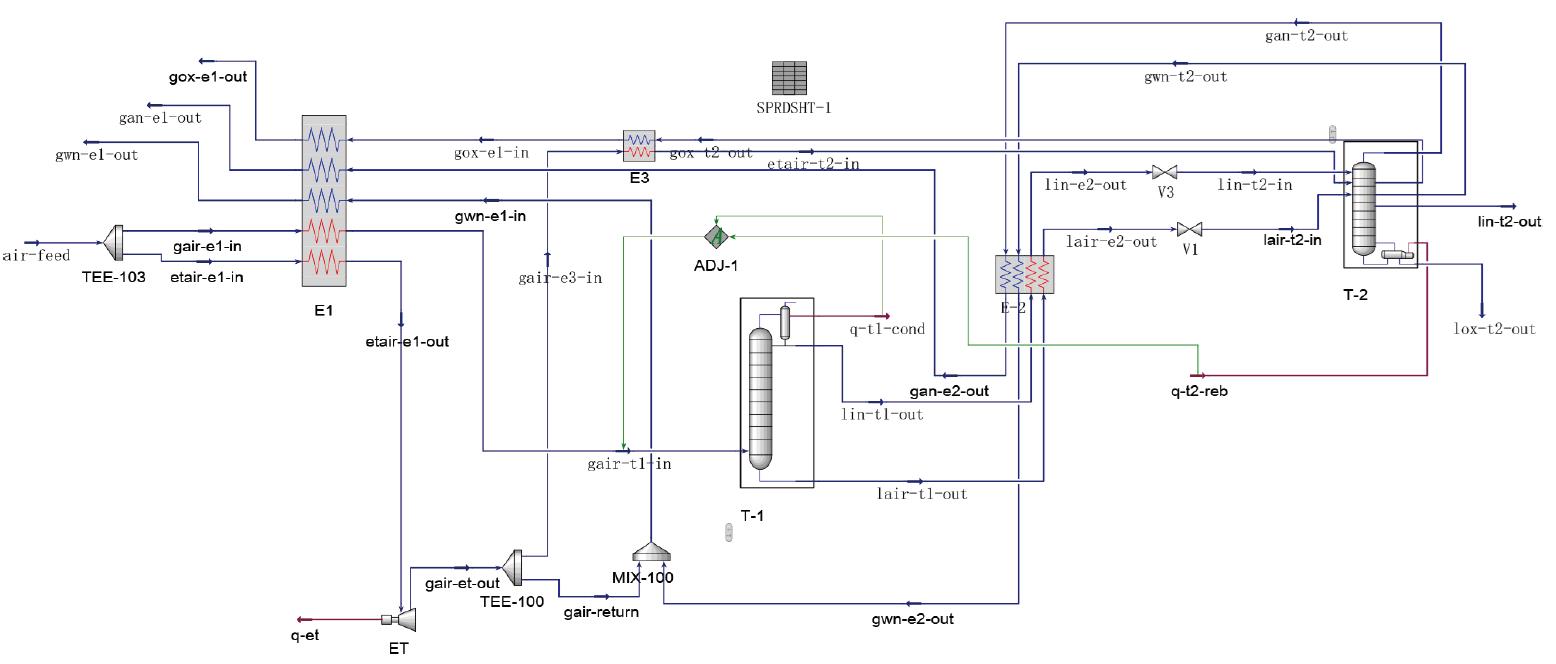

1.External Compression Air Separation Unit

• Working Principle: The low-pressure gas from the cold box is compressed to the desired pressure by external compressors.

• Process Characteristics: Expanded air enters the upper column, with a smaller iquid volume and lower product pressure (generally less than 3.0MPa)

• Advantages: Relatively simple structure and easy maintenance.

• Applications: Sultable tor applications with low product pressure requirements and less demanding system complexity.

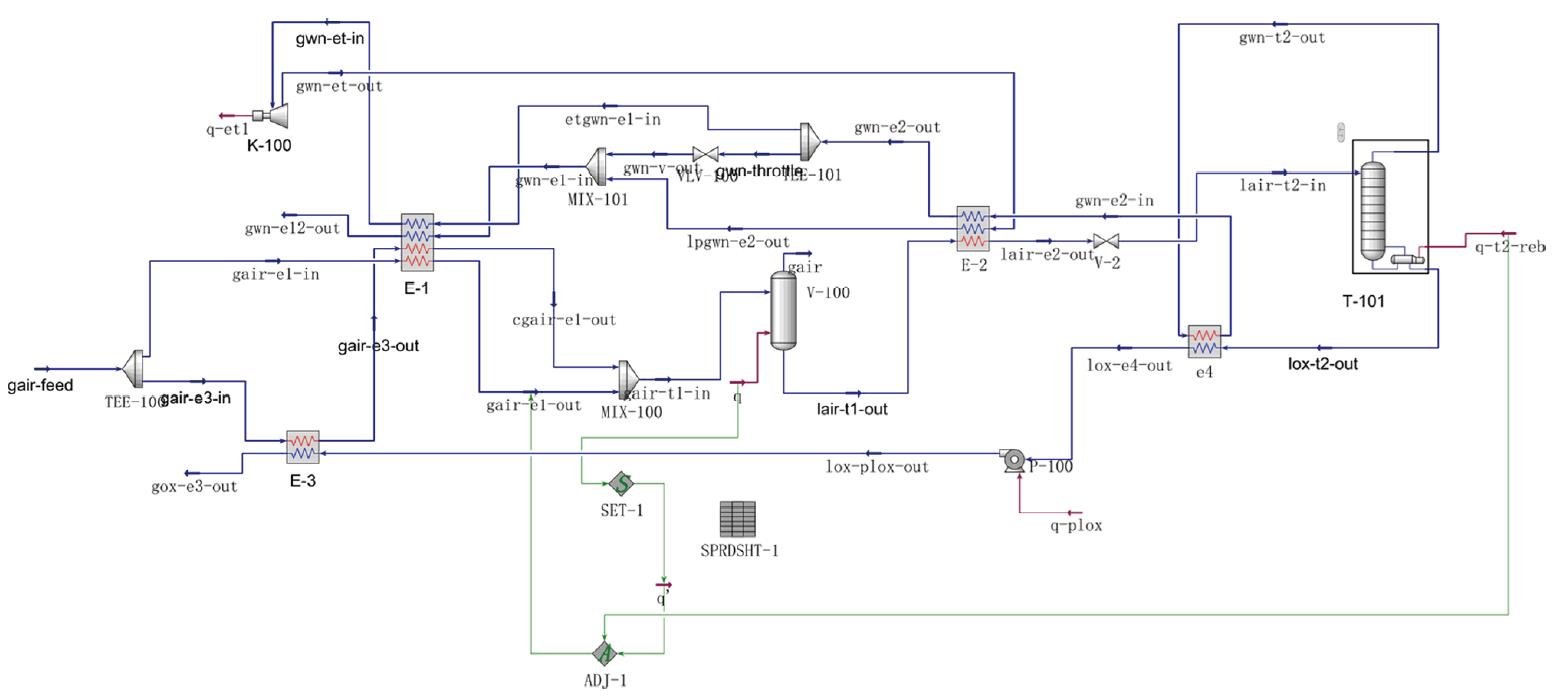

2.Internal Compression Air Separation Unit

• Working Principle: The iquid oxygen'nitrogen is pressurized by low-temperature liquid pumps and then reheated before entering the user's pipeline.

• Process Characteristics: Expanded air enters the ower column. with a larger iouid volume and hioher product pressure (aeneralv less than 10 0MPa

• Advantages: High product pressure to meet high-pressure gas demands.

• Applications: Suitable for applications with hioh product pressure requirements and can tolerate higher system complexity

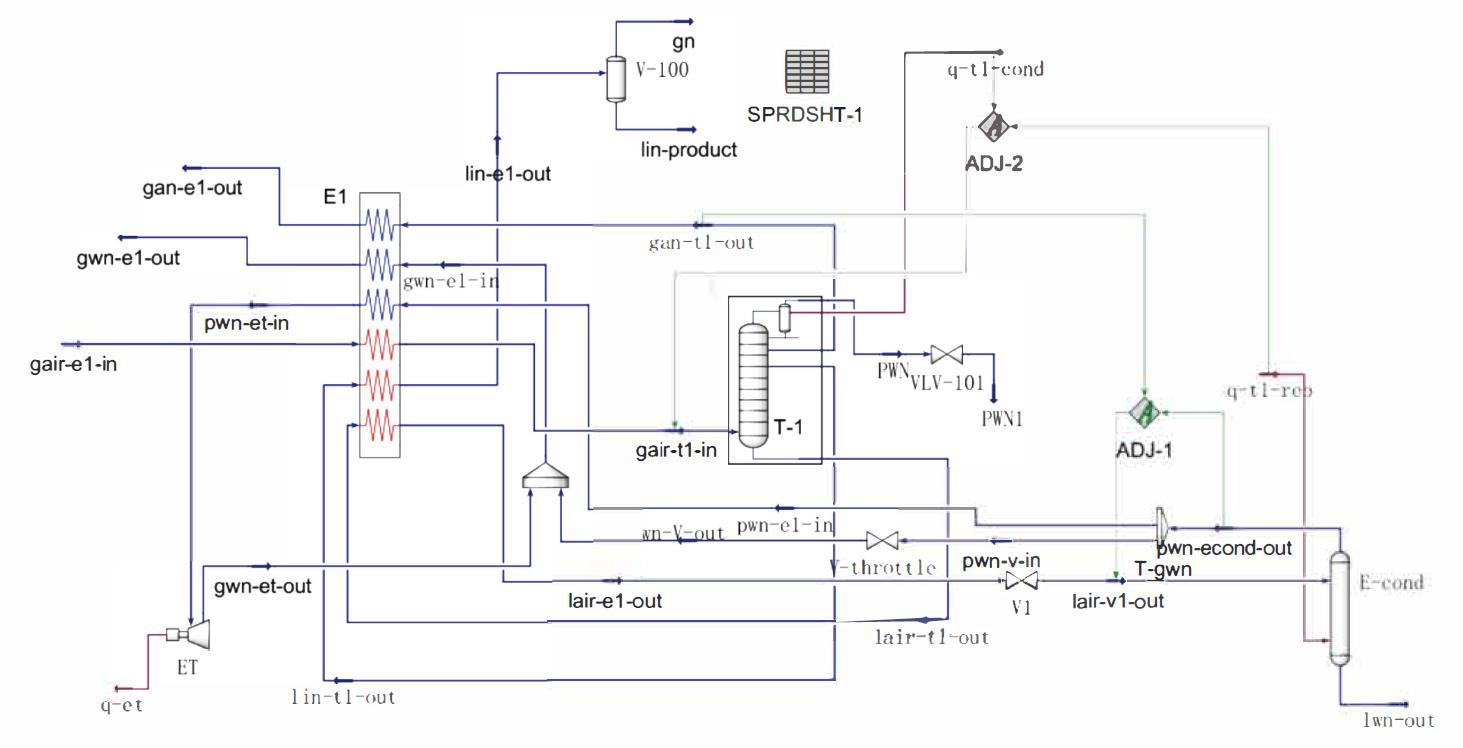

3. High-Purity Nitrogen Unit

• Working Principle: Produces high-purity nitrogen and liquid nitrogen through the air separation process

• Process Characteristics: Various process types can be selected based on requirements.

• Advantages: High product purity to meet various application requirements.

• Applications: Widely used in electronics, chemical, metalurgical, and other industries where high-purity nitrogen is required

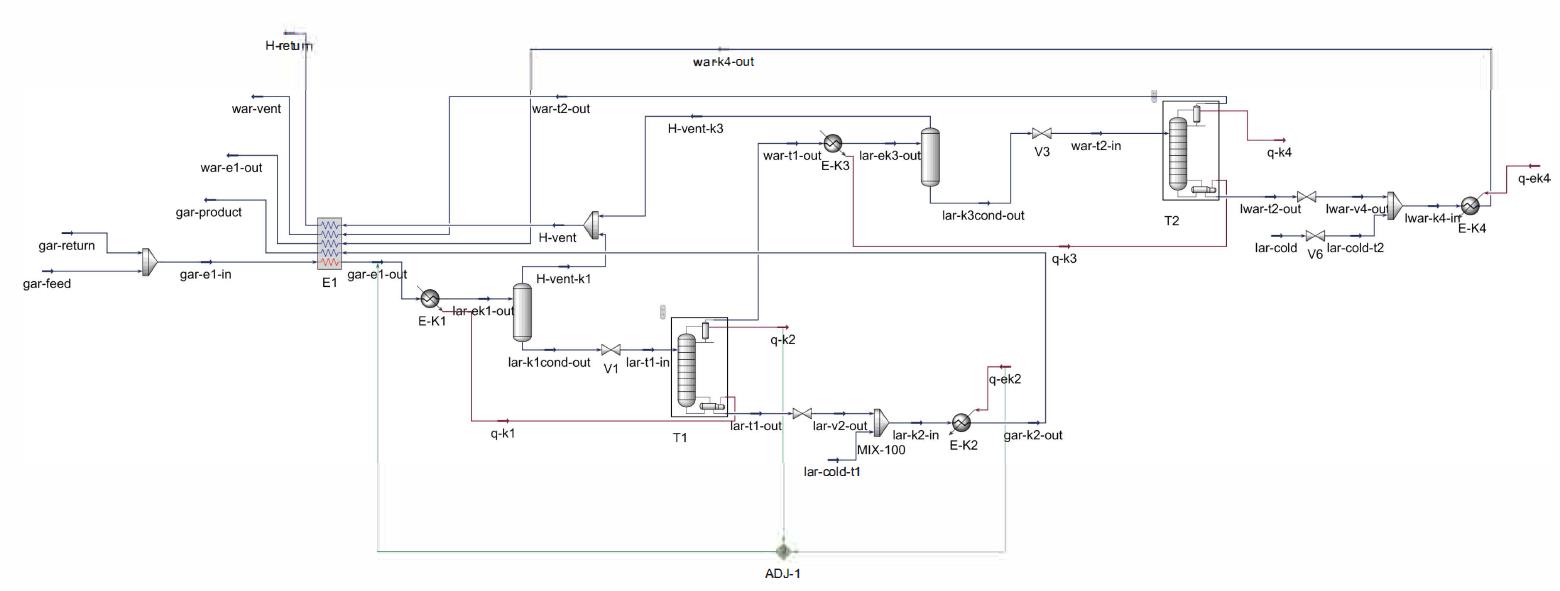

4. Argon Recovery Unit

• Working Principle: Separates argon from mixed gases to recover argon.

• Advantages: Reduces production costs, saves energy, and improves economic benefits.

• Applications: Suitable for applications with large argon demand and argon-containing waste gas.

5.Liquid Air Separation Plant

A ouid ar separaion ant can be considered a comtinalon of an airseparalon plan and a quelacion plant srefrigeration and hat exchange systems are simarto thosefoundin lquetacion plans of camparabe capacily. The apropriate refngeration cycle should be selected based on the required capacity. Fourtypical processes are as follows:Low pressure cycle.

• Low pressure cycle with cryogenic freezer

• Medium pressure cycle

• Medium pressure double expansion process

• The product is generally a fully liquid product, and some gaseous byproducts can be produced as required.

6. Liguefaction Plant

Oxygen, nitrogen, LNG, CNG, and specialgases are liquefed using the suficient cold generated by a cycic boosting exansion process, employing recyce compressors and expanders

Process Features

• Low pressure cycle

• Low pressure cycle with cryogenic freezer

• Medium pressure cycle with warm and cold expansion turbines

Liquid oxygen and liquid nitrogen can be produced separately or simultaneously

Characters And Transportation

|

|

|

|

FAQ

What are the methods of air separation?

Cryogenic Distillation: This is the most common method. Air is cooled to extremely low temperatures, causing it to liquefy. The liquid air is then fractionally distilled, taking advantage of the slightly different boiling points of oxygen and nitrogen, allowing them to be separated. Adsorption: This method utilizes materials like zeolites (molecular sieves) that selectively adsorb one gas component while allowing others to pass through. By cycling the adsorption and desorption processes, pure streams of oxygen or nitrogen can be obtained. Membrane Separation: This method employs specialized membranes that allow certain gases to pass through more readily than others. Oxygen molecules tend to permeate through these membranes faster than nitrogen molecules, enabling their separation. These methods are used to produce a variety of industrial gases with diverse applications in various sectors.

What are core equipments of cryogenic distillation air separation?

Air Compressor: This component compresses atmospheric air to the necessary pressure levels to initiate the liquefaction process. Heat Exchangers: These vital components facilitate efficient heat transfer within the system. They serve to pre-cool the compressed air, recover valuable cold energy from the process streams, and maintain the requisite low temperatures throughout the system. Molecular Sieve Beds: These beds are employed to meticulously remove impurities such as water vapor and carbon dioxide from the compressed air prior to its entry into the main cryogenic section. These impurities have the potential to solidify at the extremely low temperatures encountered within the process, potentially leading to obstructions and operational disruptions. Distillation Columns: These constitute the heart of the air separation process. They incorporate trays or packing materials that effectively facilitate the separation of oxygen and nitrogen based on their inherent differences in boiling points. Expanders: These devices ingeniously convert the pressure energy inherent within the compressed air into useful work, contributing significantly to the overall refrigeration cycle and consequently reducing energy consumption.

What is oxygen extraction rate of air separation?

Oxygen Extraction Rate: The ratio of the mass of oxygen produced by the air separation unit (ASU) to the mass of oxygen present in the incoming air stream. Key Factors Influencing Oxygen Extraction Rate: ASU Design and Technology: The efficiency of the distillation columns, heat exchangers, and other components directly impacts the amount of oxygen that can be recovered. Advanced technologies like high-efficiency expanders and improved heat exchanger designs can significantly enhance extraction rates. Operating Conditions: Factors like operating pressure, temperature, and flow rates can influence the separation efficiency. Air Quality: The presence of impurities in the incoming air stream can affect the performance of the ASU and reduce oxygen extraction. Modern cryogenic air separation units typically achieve oxygen extraction rates of 95-98%.

What are the air quality requirements for an air separation unit?

Moisture Content: Low moisture levels are crucial: Water vapor can freeze within the cryogenic system, causing blockages and operational disruptions. Efficient dryers: ASUs typically incorporate drying systems, such as molecular sieve beds, to remove moisture from the incoming air. Particulate Matter: Minimizing particulates: Dust, dirt, and other particulates can damage delicate equipment like valves and bearings within the ASU. Filtration systems: High-efficiency filters are used to remove particulate matter from the incoming air stream. Hydrocarbons: Hydrocarbons can contaminate products: Hydrocarbons can condense within the cryogenic system, potentially contaminating the final oxygen and nitrogen products. Hydrocarbon removal: Catalytic converters or other methods may be used to remove hydrocarbons from the air stream. Other Contaminants: Trace gases: Depending on the location and source of the intake air, trace gases such as sulfur dioxide, nitrogen oxides, and carbon monoxide may be present. Impact on operations: These contaminants can affect the efficiency of the separation process and may require additional treatment steps. Temperature and Pressure: Consistent conditions: While not directly related to air quality, consistent ambient temperature and pressure conditions are important for optimal ASU operation. Meeting these air quality requirements is essential for the reliable and efficient operation of an ASU, ensuring the production of high-purity oxygen and nitrogen products.

Factory

Related Product