By integrating design and operation, leveraging automation and simulation tools, and implementing digital handover, 4D simulation, and VR training, we can optimize the entire project lifecycle. This approach covers all stages, from initial basic and detailed design through construction, commissioning, and handover, to future upgrades and revamps, ensuring a seamless and efficient process.

Some design softwares and systems list as follows

AutoCAD Plant3D

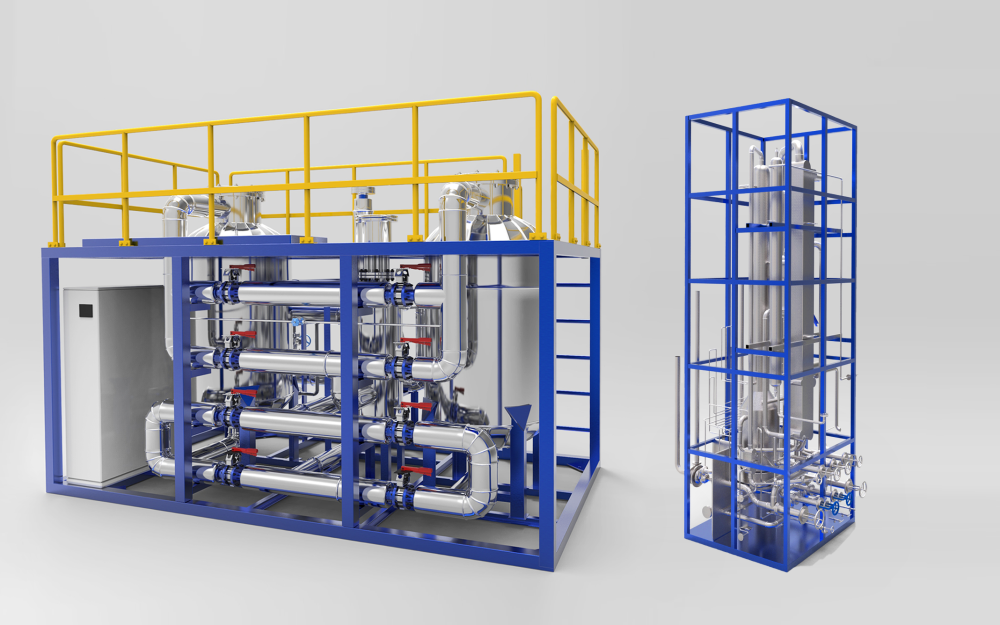

Utilize AutoCAD Plant3D to engineer cold box piping and pipeline systems. Streamline pipeline layouts to reduce flow resistance, expedite the design process, and improve the accuracy of on-site installation of prefabricated modular components.

STAAD.Pro

Leverage STAAD.Pro, an integrated Finite Element Analysis and Design software, to comprehensively evaluate all structures subjected to static loads, dynamic responses, wind loads, seismic loads, and moving loads. This comprehensive analysis will ensure the reliability and structural integrity of the steel structure.

AutoPIPE

Utilize AutoPIPE, a specialized stress analysis software, to perform comprehensive mechanical analysis on the pipeline system within the cold box. This rigorous analysis guarantees the safety and integrity of the pipeline system, as well as the connected machinery and civil infrastructure. AutoPIPE offers a wide range of international and domestic pipeline design standards for comprehensive and accurate engineering solutions.

Aspen Hysys

Leverage process simulation software, such as Aspen Hysys, to optimize process parameters, reduce the liquid level in main condensers, minimize temperature differentials at the hot ends of PFHEs, accelerate design timelines, and reduce overall plant energy consumption.

COMOS

Utilize COMOS, an integrated intelligent engineering software, leverages a single database to streamline digital engineering, plant handover, and intelligent operation processes. Key features include robust engineering data management, efficient equipment operation and maintenance, seamless system collaboration, immersive VR training, and integrated construction, engineering operation, and intelligent control capabilities. This powerful platform enables multi-dimensional and life-cycle remote operation and maintenance services for ASU plants, centrally managed from our Hangzhou office.