- Product Detail

-

Pressure Swing Adsorption (PSA) for Hydrogen Production

Pressure Swing Adsorption (PSA) is a technology used to separate specific gas species from a mixture of gases under pressure. It's widely employed in the production of high-purity hydrogen gas.

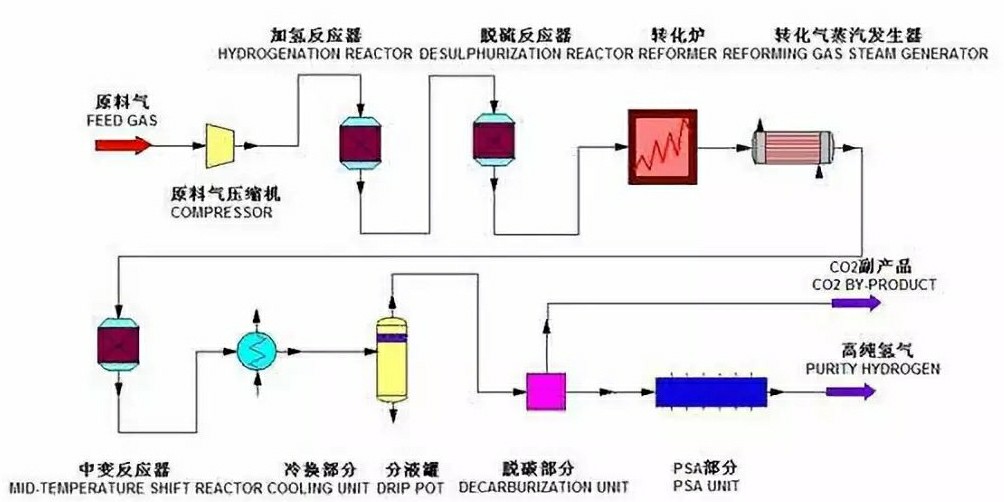

How PSA Works for Hydrogen Production

Adsorption:

A gas mixture, often a hydrogen-rich stream from processes like steam methane reforming or water electrolysis, is passed through a bed of adsorbent material (typically a zeolite or carbon molecular sieve).

Under high pressure, the adsorbent selectively adsorbs impurities like carbon dioxide, methane, and water vapor, allowing the hydrogen to pass through.

Desorption:

Once the adsorbent becomes saturated with impurities, the pressure is reduced, causing the adsorbent to release the adsorbed gases.

This process is known as desorption.

Cycle Repetition:

Multiple adsorbent beds are used in a cyclical process to ensure continuous hydrogen production.

While one bed is adsorbing impurities, another is being regenerated.

Advantages of PSA for Hydrogen Production

High Purity: PSA can produce high-purity hydrogen, often exceeding 99.999% purity.

Energy Efficiency: The process is relatively energy-efficient, especially when compared to other separation techniques.

Flexibility: PSA systems can be designed to handle various feed gas compositions and flow rates.

Compact Design: PSA units are compact and require minimal space.

Low Operating Costs: The process has low operating costs, making it economically attractive.

Gas sources:

Methanol cracking gas, ammonia cracking gas, methanol tail gas, formaldehyde tail gas,

Synthesis gas, refinery gas, hydrocarbon steam reforming gas, fermentation gas, polysilicon tail gas,

Semi-water gas, town gas, coke oven gas

Refinery catalytic cracking dry gas, refinery reforming tail gas

Other H₂-containing gas sources

Technical parameters:

Operating Pressure: 0.4~4.0MPa (gauge pressure)

Operating Temperature: Ambient temperature

Product Output: H₂

H₂ Purity: 98~99.999% (V), adjustable based on customer requirements

H₂ Recovery: 80~98%

System Pressure Drop: 0.05~0.1MPa

Output Temperature: Ambient temperature

Note: H₂ recovery is related to feed gas composition, pressure, and product H₂ purity.

Pressure Swing Adsorption (PSA)

Pressure Swing Adsorption (PSA) is a technology used to separate specific gas species from a mixture of gases under pressure. It's widely employed in the production of high-purity hydrogen gas.

Categories:

keyword:

Pressure Swing Adsorption (PSA)

Factory

FAQ

Related Product