- Product Detail

-

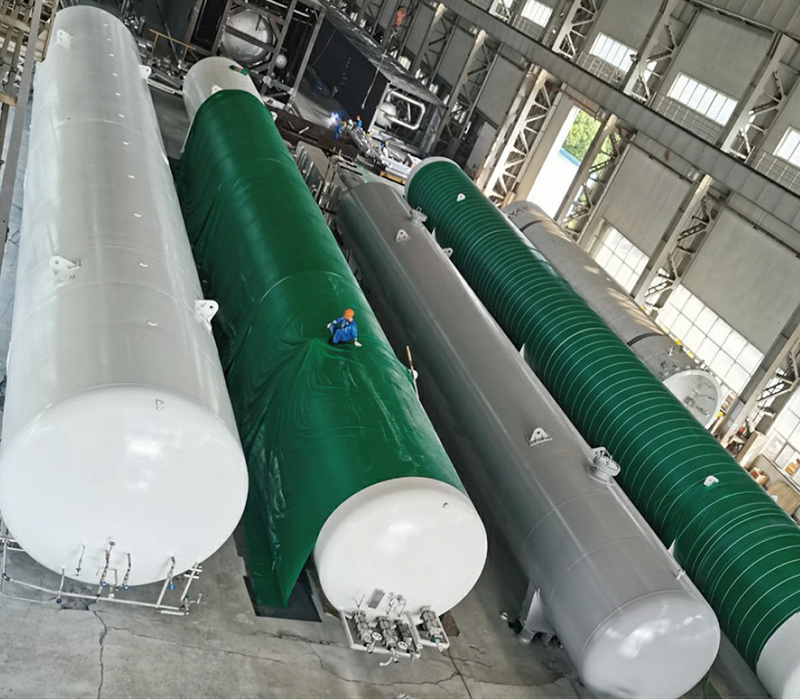

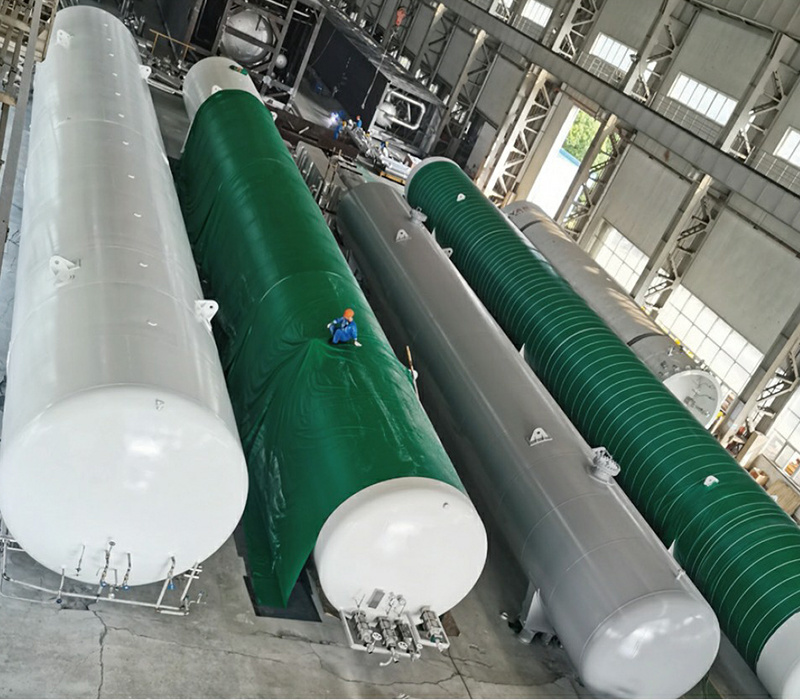

Cryogenic Storage Tanks for Air Separation Units

Cryogenic storage tanks are essential components of Air Separation Units (ASUs) used to store liquefied gases such as oxygen, nitrogen, and argon at extremely low temperatures. These tanks are specifically designed to maintain the cryogenic state of the gases, ensuring their quality and availability for various applications.

Benefits of Cryogenic Storage Tanks:

• Efficient Storage: These tanks enable the storage of large quantities of liquefied gases in a compact space.

• Reliable Supply: They ensure a continuous and reliable supply of gases, even during periods of peak demand or supply disruptions.

• Cost-Effective: By storing gases in liquid form, transportation and storage costs can be significantly reduced.

• Environmental Friendliness: Cryogenic storage minimizes the environmental impact associated with the transportation and distribution of gases.

Vacuum Storage Tanks

Vacuum storage tanks are crucial components in industrial gas lines, particularly for storing cryogenic gases like liquid nitrogen, oxygen, and argon. These tanks are designed to maintain extremely low temperatures and high pressures, ensuring the quality and purity of the stored gases.

Key Components and Functioning:

1.Inner Vessel: This is where the cryogenic liquid is stored. It's typically made of high-grade stainless steel to withstand extreme cold temperatures and pressure.

2.Outer Vessel: This encloses the inner vessel, providing structural support and protection.

3.Vacuum Jacket: The space between the inner and outer vessels is evacuated to create a high vacuum. This vacuum acts as an excellent insulator, minimizing heat transfer and maintaining the low temperature of the stored gas.

4.Perlite Powder: This powder is often used to fill the vacuum space, further enhancing the insulation properties.

5.Pressure Relief Valves: These valves are essential for safety, releasing excess pressure if it builds up within the tank.

6.Vacuum Pumps: These pumps are used to maintain the high vacuum in the jacket, ensuring optimal insulation.

Advantages of Vacuum Storage Tanks:

• Efficient Storage: These tanks can store large volumes of cryogenic gases in a compact space, optimizing storage capacity.

• Reduced Energy Consumption: The high vacuum insulation significantly reduces the energy required to maintain low temperatures, leading to lower operating costs.

• Improved Product Quality: By minimizing heat transfer, vacuum storage tanks help preserve the purity and quality of the stored gases.

• Enhanced Safety: The robust construction and safety features of these tanks reduce the risk of accidents and leaks.

• Long-Term Reliability: Vacuum storage tanks are designed for long-term, reliable operation, ensuring a consistent supply of industrial gases.

Main Technical Parameters of Vacuum Storage TankEffective volume(m3)

Working pressure(kPa)

Dimension(mm)

Empty weight(Kgs)

Static evaporation rate(%day)

LOX

LIN

LAr

5

0.8

ϕ 2016x5050

4200

0.43

0.65

0.46

5

1.6

ϕ 2016x5050

4500

0.43

0.65

0.46

10

0.8

ϕ 2416x6050

6400

0.36

0.55

0.38

10

1.6

ϕ 2416x6050

7300

0.36

0.55

0.38

15

0.8

ϕ 2416x8150

8600

0.35

0.53

0.37

15

1.6

ϕ 2416x8150

9700

0.35

0.53

0.37

20

0.8

ϕ 2416x10150

10600

0.33

0.5

0.35

20

1.6

ϕ 2416x10150

12500

0.33

0.5

0.35

30

0.8

ϕ 2520x12050

13900

0.29

0.44

0.31

30

1.6

ϕ 2620x12100

15300

0.29

0.44

0.31

50

0.8

ϕ 3020x13050

22500

0.23

0.35

0.24

50

1.6

ϕ 3224x12050

24100

0.23

0.35

0.24

100

0.8

ϕ 3724x16550

44500

0.16

0.25

0.17

100

1.6

ϕ 3824x15900

43000

0.16

0.25

0.17

150

0.8

ϕ 4428x17200

52200

0.14

0.22

0.15

150

1.6

ϕ 4428x17200

60900

0.14

0.22

0.15

200

0.8

ϕ 4428x22050

76600

0.13

0.2

0.14

250

0.8

ϕ 4632x24450

80500

0.12

0.18

0.13

300

0.8

ϕ 4632x30100

115200

0.11

0.16

0.12

Large Scale Cryogenic Liquid Storage Tank

• Adopt cutting-edge design and construction technologies to optimize the process flow and enhance the structural integrity of the tank

• The structure is a vertical, cylindrical, double-walled storage tank with a flat bottom and an arched cover. Powder accumulation is employed for thermal insulation. The tank primarily consists of an inner tank, an outer tank, and a thermal insulation interlayer.

• 300-50000m3 volume

• 10-40Kpa pressure

• LOX, LIN, LAr, LNG, liquid ethylene etc. mediumMain Technical Parameters of Liquid Oxygen/Nitrogen/Argon Storage Tanks

Effective volume(m3)

Working pressure(kPa)

Dimension(mm)

Empty weight(T)

Static evaporation rate(%day)

LOX

LIN

LAr

300

15

ϕ 9800x11200

107

0.29

0.45

0.31

400

25

ϕ 10300x12100

135

0.26

0.45

0.28

500

15

ϕ 11200x11900

137

0.25

0.39

0.27

600

15

ϕ 11500x13100

150

0.23

0.36

0.25

1000

15

ϕ 12200x17300

215

0.19

0.30

0.20

1500

15

ϕ 14200x18500

296

0.16

0.25

0.17

2000

25

ϕ 18300x16200

436

0.15

0.23

0.16

3000

15

ϕ 18300x22000

469

0.13

0.20

0.14

4000

15

ϕ 21200x20500

610

0.11

0.17

0.12

5000

15

ϕ 23000x21800

657

0.10

0.16

0.11

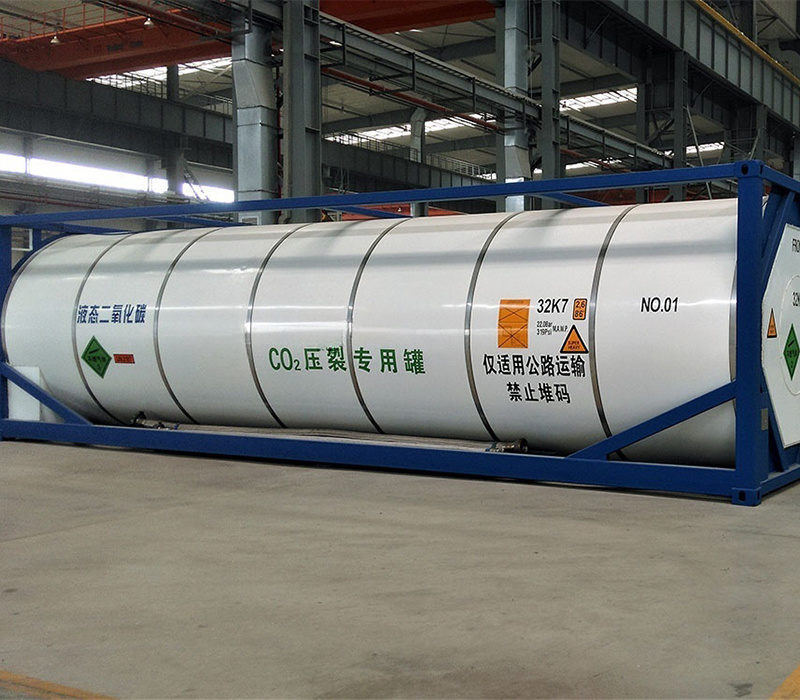

ISO Tank: A Versatile Shipping Solution

An ISO tank, or Intermodal Tank Container, is a specialized container designed for the efficient transportation of bulk liquid and gas substances. These tanks are built to international standards and can be seamlessly transported by various modes, including sea, rail, and road.

Key Features of ISO Tanks:

• Standardized Dimensions: ISO tanks adhere to specific dimensions and configurations, ensuring compatibility with various transportation modes.

• Robust Construction: They are built to withstand harsh conditions and rigorous handling during transportation.

• Variety of Materials: ISO tanks are constructed from various materials, including stainless steel, aluminum, and specialized alloys, to accommodate different substances.

• Safety Features: Equipped with safety valves, pressure relief devices, and other safety measures to prevent accidents and spills.

• Customizable Configurations: ISO tanks can be customized to meet specific requirements, such as insulation, heating, and cooling systems.

On the basis of its long-time experience in manufacturing of pressure vessels, YIHO has implemented into the production ISO T75 cryogenic tanks for liquid oxygen (LOX), liquid argon (LAR), liquid nitrogen (LIN), liquid carbon dioxide (LCO2) and liquefied natural gas (LNG), as well as T22 tanks for low pressure chemicals such as Anhydrous Hydrogen Fluoride (AHF), T50 tanks for high pressure liquefied gases such as propane, butane.Micro Bulk (Perma-Cyls)

Micro bulk is a gas delivery system that offers a convenient and efficient alternative to traditional cylinder-based supply methods. It involves the use of small, insulated storage tanks, often referred to as Perma-Cyls, which are filled with cryogenic gases like nitrogen, oxygen, argon, or carbon dioxide.

How Micro bulk Works

1.Storage: The Perma-Cyl stores the gas in a cryogenic liquid state, significantly increasing the amount of gas that can be stored compared to traditional cylinders.

2.Vaporization: As needed, the liquid gas is vaporized and delivered to the point of use through a regulated delivery system.

3.Refilling: The Perma-Cyl is periodically refilled by a specialized delivery truck, ensuring a continuous supply of gas.

Advantages of Micro bulk

• Increased Efficiency: Micro bulk systems offer higher efficiency and lower operating costs compared to cylinder-based systems.

• Reduced Downtime: By eliminating the need for frequent cylinder changes, micro bulk systems minimize downtime and improve productivity.

• Improved Safety: Micro bulk systems are designed to be safe and reliable, with advanced safety features to prevent accidents.

• Ease of manufacturing, installation, maintenance, and use: The design should facilitate these processes.

• Low cost and material efficiency: It is important to minimize costs and conserve materials, especially expensive ones like stainless steel and non-ferrous metals.

• Environmental Benefits: Micro bulk systems can reduce the carbon footprint associated with gas delivery by minimizing the number of delivery trips and reducing the use of disposable cylinders.Applications of Micro bulk

Micro bulk systems are widely used in various industries, including:

• Healthcare: For medical gas supply in hospitals and clinics.

• Manufacturing: For industrial processes such as welding, cutting, and heat treating.

• Food and Beverage: For food processing and packaging applications.

• Laboratory: For scientific research and analysis.

ISO & Storage Tanks

Cryogenic storage tanks are essential components of Air Separation Units (ASUs) used to store liquefied gases such as oxygen, nitrogen, and argon at extremely low temperatures. These tanks are specifically designed to maintain the cryogenic state of the gases, ensuring their quality and availability for various applications.

Categories:

keyword:

ISO & Storage Tanks

Factory

FAQ

Related Product