Air separation and liquefaction plant

Date: 2024-12-31

Air Separation Unit (ASU): A Brief Introduction

Air Separation Unit (ASU) is an industrial facility that separates atmospheric air into its primary components: nitrogen, oxygen, and sometimes argon. This process is achieved through a series of complex steps that involve cooling the air to extremely low temperatures (cryogenic temperatures).

• Air Intake and Filtration: Atmospheric air is drawn into the ASU and filtered to remove impurities like dust and moisture.

• Compression: The filtered air is compressed to increase its pressure.

• Cooling and Purification: The compressed air is cooled and further purified to remove any remaining contaminants.

• Cryogenic Separation: The cooled, purified air is then cooled to extremely low temperatures, causing it to liquefy.

The liquefied air is separated into its components through a process called fractional distillation, where different gases are separated based on their boiling points.

• Product Gas: The separated gases, nitrogen, oxygen, and argon, are then warmed and compressed to their final state, ready for storage or distribution.

The gases produced by ASU have a wide range of applications across various industries:

• Oxygen:

♦ Steelmaking

♦ Medical applications

♦ Chemical production

• Nitrogen:

♦ Food preservation

♦ Electronics manufacturing

♦ Chemical production

• Argon:

♦ Welding

♦ Metal fabrication

♦ Lighting

By efficiently separating the components of air, ASU play a crucial role in modern industries, contributing to technological advancements and supporting various essential processes.

Comparison of Air Separation Units (ASUs): External Compression, Internal Compression, High-Purity Nitrogen, and Argon Recovery Units

1. External Compression Air Separation Unit

• Working Principle: The low-pressure gas from the cold box is compressed to the desired pressure by external compressors.

• Process Characteristics: Expanded air enters the upper column, with a smaller liquid volume and lower product pressure (generally less than 3.0MPa).

• Advantages: Relatively simple structure and easy maintenance.

• Applications: Suitable for applications with low product pressure requirements and less demanding system complexity.

2. Internal Compression Air Separation Unit

• Working Principle: The liquid oxygen/nitrogen is pressurized by low-temperature liquid pumps and then reheated before entering the user's pipeline.

• Process Characteristics:Expanded air enters the lower column, with a larger liquid volume and higher product pressure (generally less than 10.0MPa).

• Advantages: High product pressure to meet high-pressure gas demands.

• Applications: Suitable for applications with high product pressure requirements and can tolerate higher system complexity.

3. High-Purity Nitrogen Unit

• Working Principle: Produces high-purity nitrogen and liquid nitrogen through the air separation process.

• Process Characteristics: Various process types can be selected based on requirements.

• Advantages: High product purity to meet various application requirements.

• Applications: Widely used in electronics, chemical, metallurgical, and other industries where high-purity nitrogen is required.

4. Argon Recovery Unit

• Working Principle: Separates argon from mixed gases to recover argon.

• Advantages: Reduces production costs, saves energy, and improves economic benefits.

• Applications: Suitable for applications with large argon demand and argon-containing waste gas.

Summary of Comparison

|

Unit |

Working Principle |

Process Characteristics |

Advantages |

Applications |

|

External Compression ASU |

External compressor pressurization |

Expanded air enters upper column, small liquid volume, low pressure |

Simple structure, easy maintenance |

Low pressure requirement, low system complexity |

|

Internal Compression ASU |

Low-temperature liquid pump pressurization |

Expanded air enters lower column, large liquid volume, high pressure |

High pressure |

High pressure requirement, can tolerate higher system complexity |

|

High-Purity Nitrogen Unit |

Air separation process |

Various process types |

High product purity |

Electronics, chemical, metallurgical industries |

|

Argon Recovery Unit |

Mixed gas separation |

- |

Reduces costs, saves energy |

Large argon demand, argon-containing waste gas |

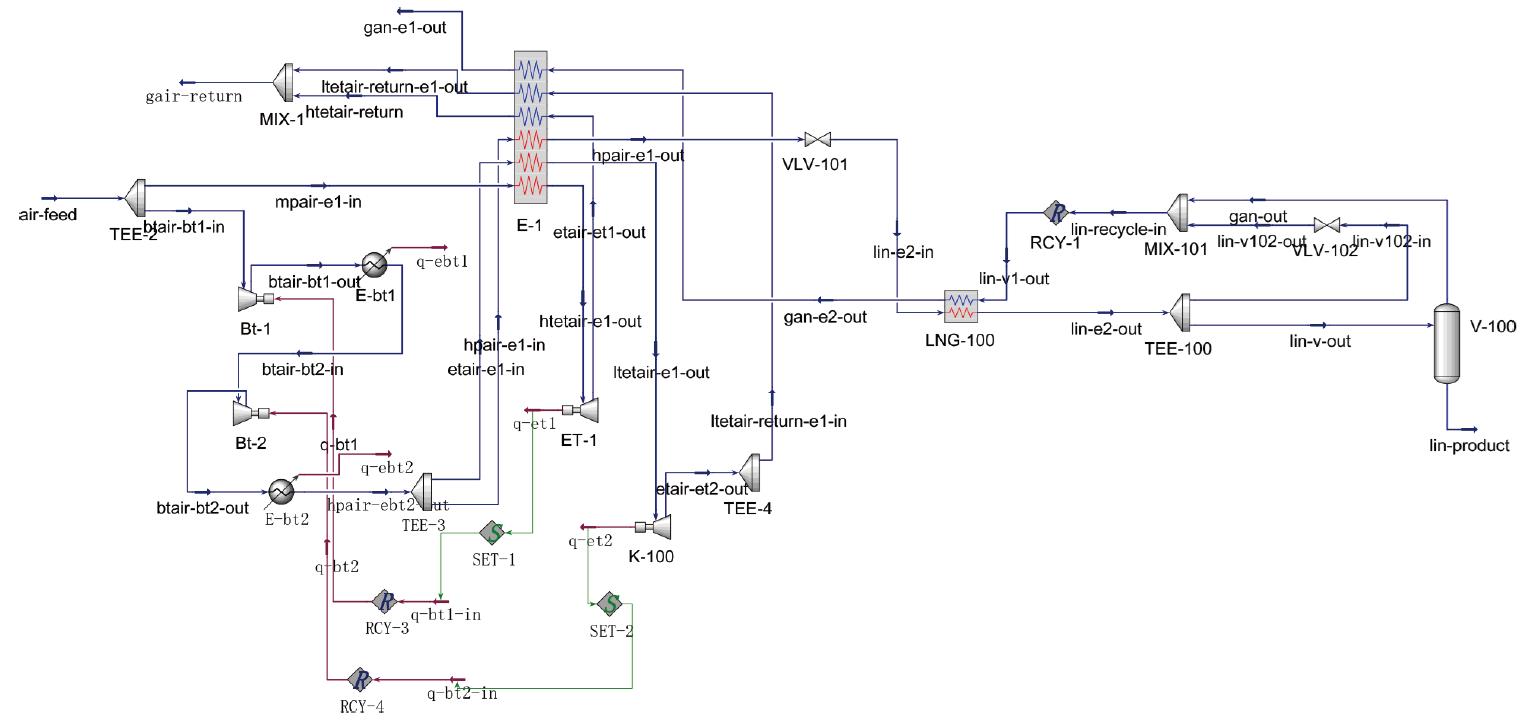

5. Liquid Air Separation Plant

A liquid air separation plant can be considered a combination of an air separation plant and a liquefaction plant. Its refrigeration and heat exchange systems are similar to those found in liquefaction plants of comparable capacity. The appropriate refrigeration cycle should be selected based on the required capacity. Four typical processes are as follows:Low pressure cycle

• Low pressure cycle with cryogenic freezer

• Medium pressure cycle

• Medium pressure double expansion process

The product is generally a fully liquid product, and some gaseous byproducts can be produced as required.

6. Liquefaction Plant

Oxygen, nitrogen, LNG, CNG, and special gases are liquefied using the sufficient cold generated by a cyclic boosting expansion process, employing recycle compressors and expanders.

Process Features

• Low pressure cycle

• Low pressure cycle with cryogenic freezer

• Medium pressure cycle with warm and cold expansion turbines

Liquid oxygen and liquid nitrogen can be produced separately or simultaneously.

The choice of unit depends on the following factors:

• Product Pressure Requirements: For high product pressure requirements, choose an internal compression ASU.

• Product Purity Requirements: For high product purity requirements, choose a high-purity nitrogen unit.

• Economy: For large argon demand and argon-containing waste gas, choose an argon recovery unit.

• System Complexity: For low system complexity requirements, choose an external compression ASU

Workflows

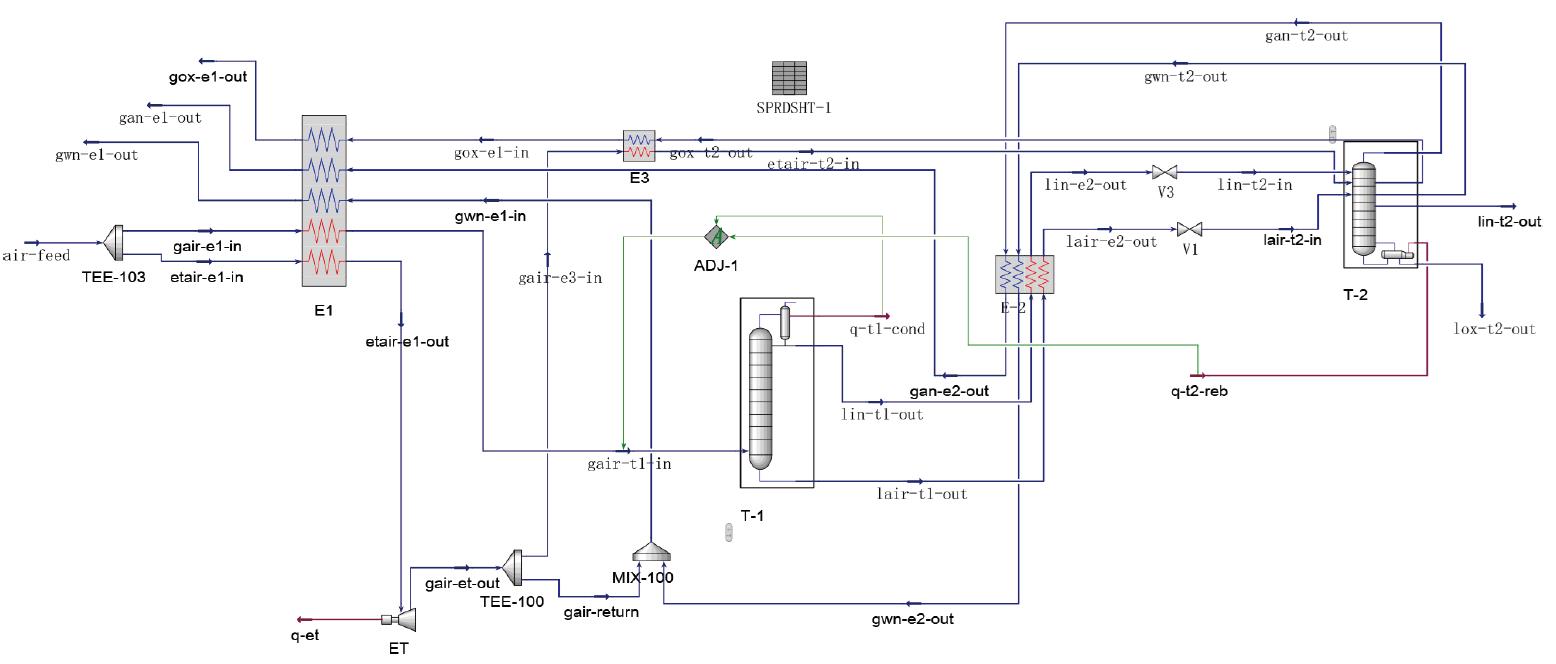

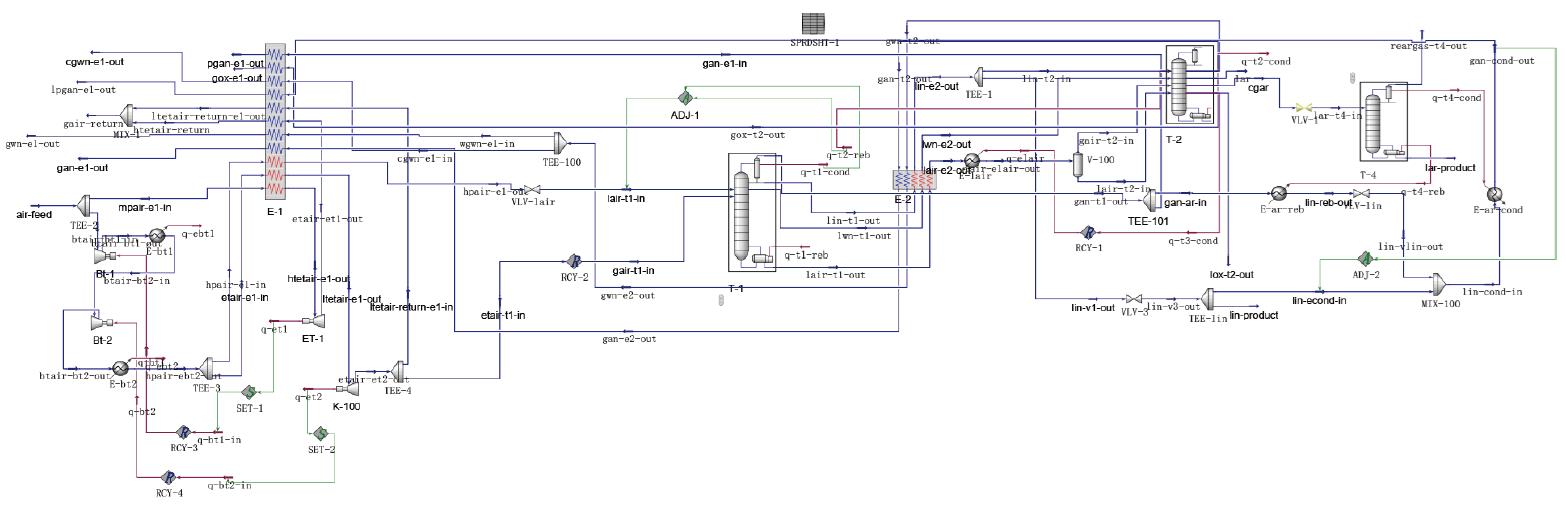

1.External Compression Air Separation Unit

• Working Principle: The low-pressure gas from the cold box is compressed to the desired pressure by external compressors.

• Process Characteristics: Expanded air enters the upper column, with a smaller iquid volume and lower product pressure (generally less than 3.0MPa)

• Advantages: Relatively simple structure and easy maintenance.

• Applications: Sultable tor applications with low product pressure requirements and less demanding system complexity.

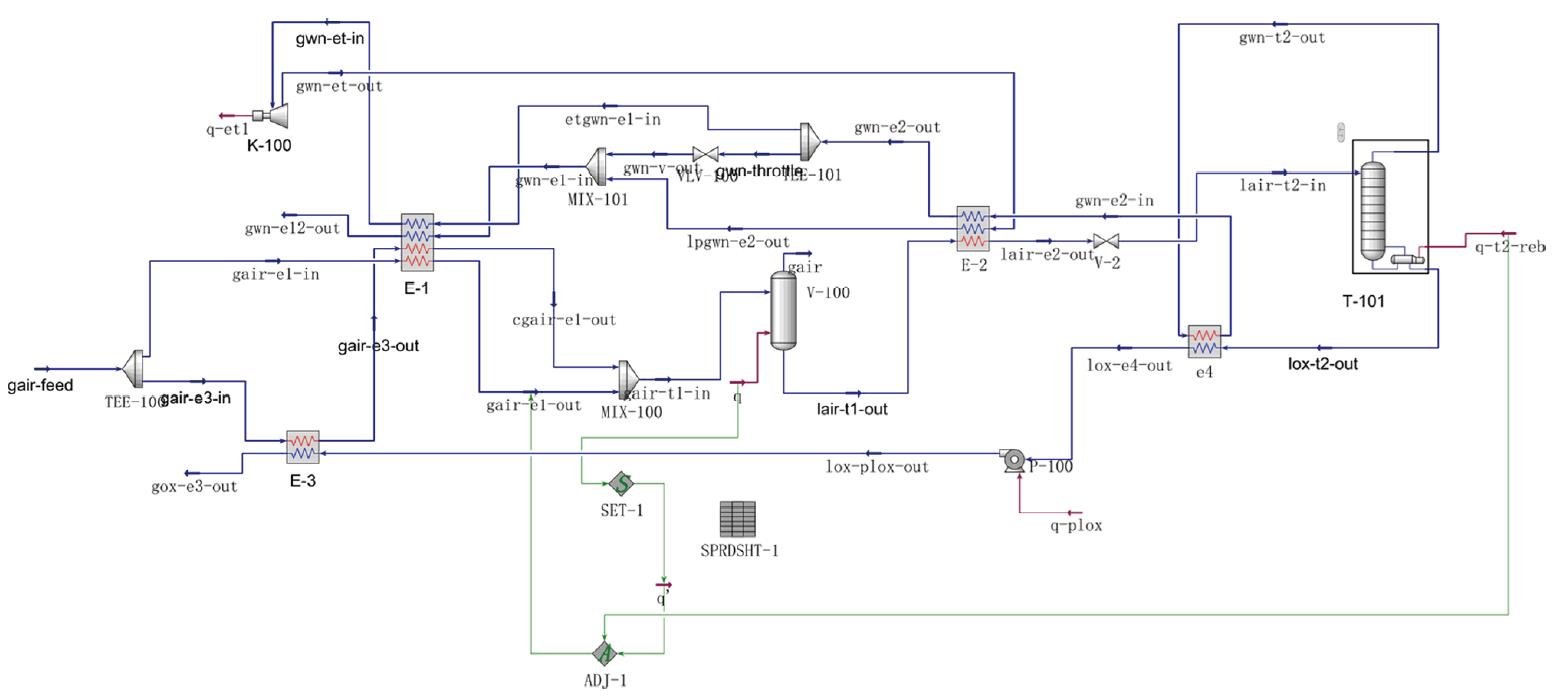

2.Internal Compression Air Separation Unit

• Working Principle: The iquid oxygen'nitrogen is pressurized by low-temperature liquid pumps and then reheated before entering the user's pipeline.

• Process Characteristics: Expanded air enters the ower column. with a larger iouid volume and hioher product pressure (aeneralv less than 10 0MPa

• Advantages: High product pressure to meet high-pressure gas demands.

• Applications: Suitable for applications with hioh product pressure requirements and can tolerate higher system complexity

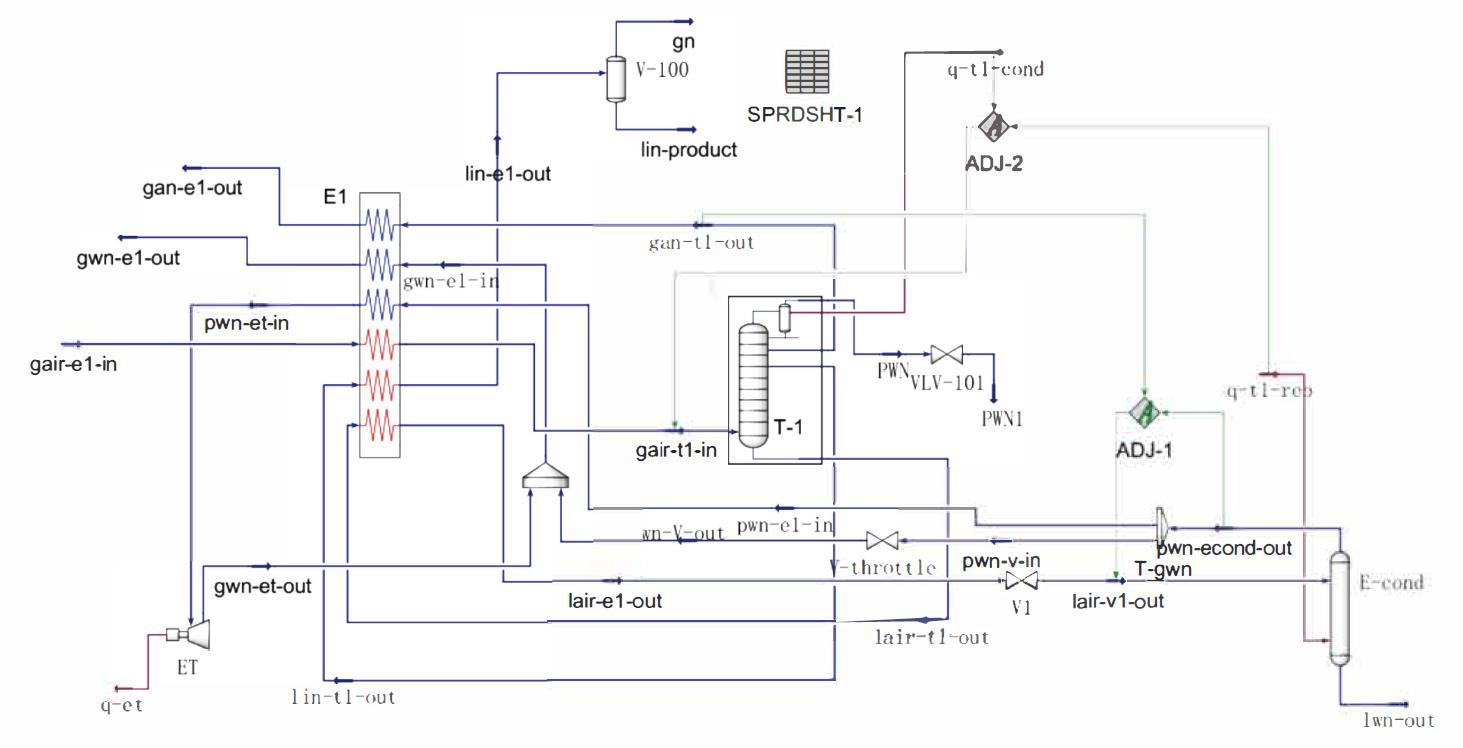

3. High-Purity Nitrogen Unit

• Working Principle: Produces high-purity nitrogen and liquid nitrogen through the air separation process

• Process Characteristics: Various process types can be selected based on requirements.

• Advantages: High product purity to meet various application requirements.

• Applications: Widely used in electronics, chemical, metalurgical, and other industries where high-purity nitrogen is required

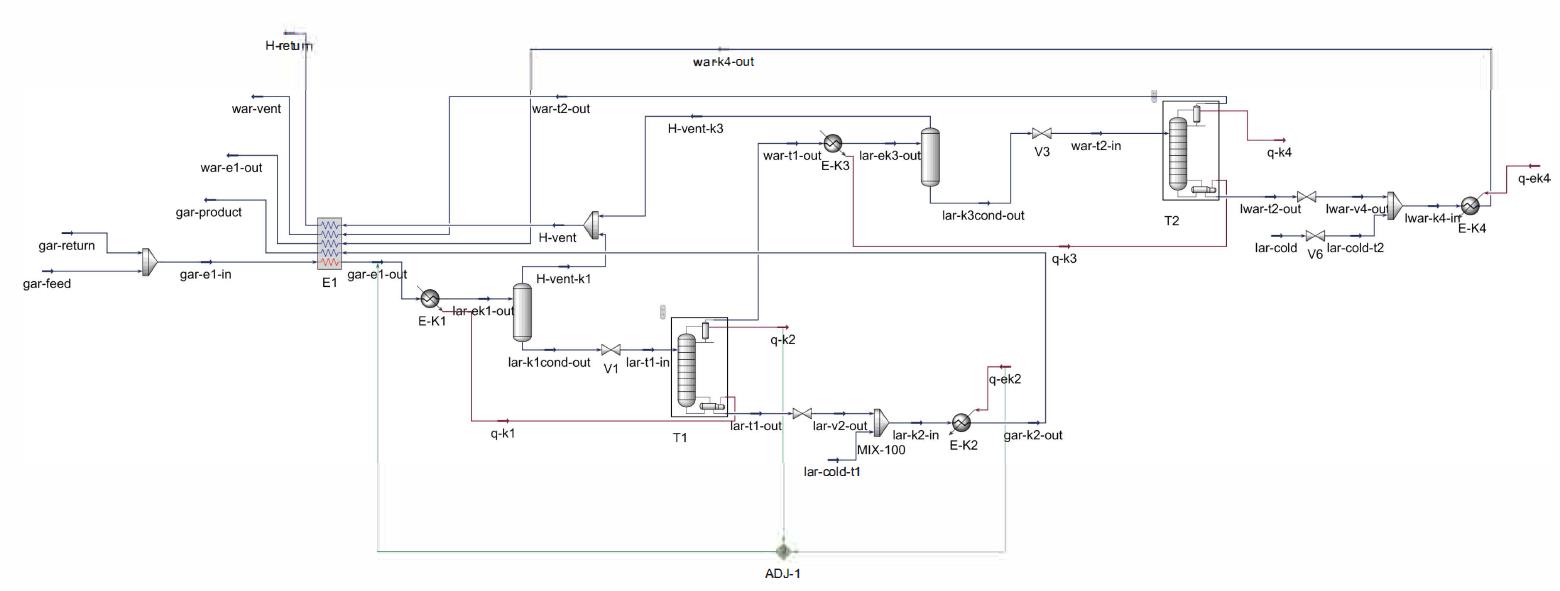

4. Argon Recovery Unit

• Working Principle: Separates argon from mixed gases to recover argon.

• Advantages: Reduces production costs, saves energy, and improves economic benefits.

• Applications: Suitable for applications with large argon demand and argon-containing waste gas.

5.Liquid Air Separation Plant

A ouid ar separaion ant can be considered a comtinalon of an airseparalon plan and a quelacion plant srefrigeration and hat exchange systems are simarto thosefoundin lquetacion plans of camparabe capacily. The apropriate refngeration cycle should be selected based on the required capacity. Fourtypical processes are as follows:Low pressure cycle.

• Low pressure cycle with cryogenic freezer

• Medium pressure cycle

• Medium pressure double expansion process

• The product is generally a fully liquid product, and some gaseous byproducts can be produced as required.

6. Liguefaction Plant

Oxygen, nitrogen, LNG, CNG, and specialgases are liquefed using the suficient cold generated by a cycic boosting exansion process, employing recyce compressors and expanders

Process Features

• Low pressure cycle

• Low pressure cycle with cryogenic freezer

• Medium pressure cycle with warm and cold expansion turbines

Liquid oxygen and liquid nitrogen can be produced separately or simultaneously

Characters And Transportation

|

|

|

|

FAQ

Factory

Related Product